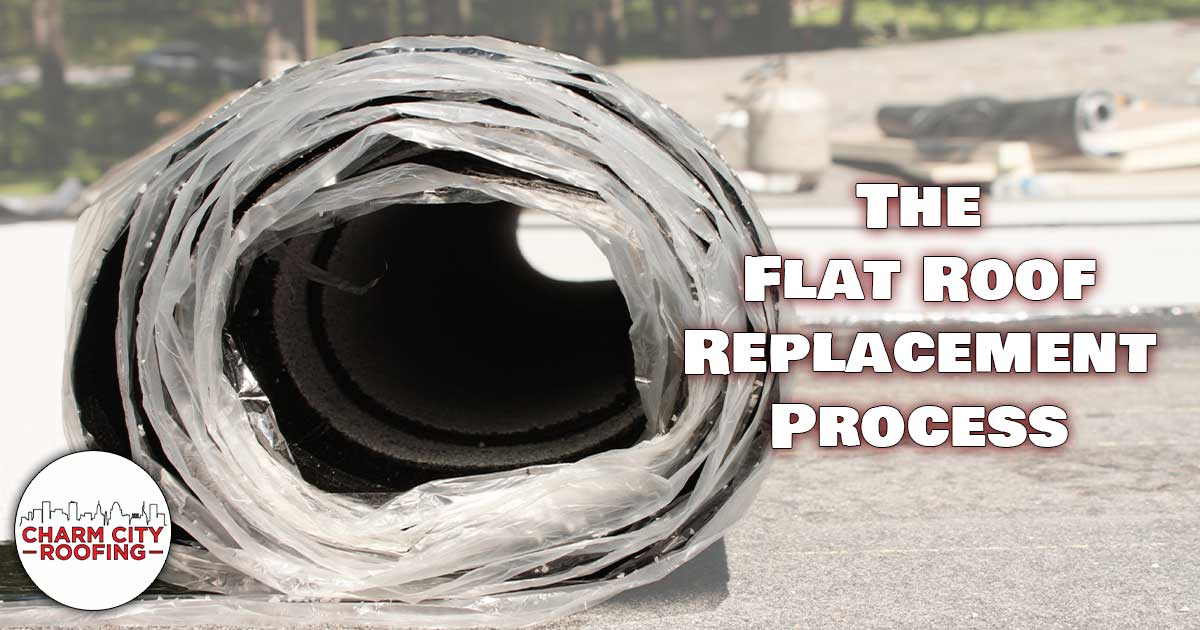

FLAT ROOF REPLACEMENT – The Whole Process

FLAT ROOF REPLACEMENT

A few years ago, we put out a video that covered the entire process of a flat roof replacement. As one of our most popular services, naturally it became one of our top viewed videos of all time. While we have a general overview of the process here on our site, n this blog article, we want to outline that process in detail. Additionally, it’s important to address some of the new options and materials we’ve adopted over time.

There’s a lot that goes into replacing a roof. Every roof is made up of various parts that work together to provide excellent protection to your home. In order to work properly, everything from structural components to insulation to waterproofing layers must be kept up to standard.

Flat roofs have a reputation for being more simple than their pitched cousins. But while they may be simple in some respects, they have unique qualities of their own to consider. For example, flat roofs are much more likely to have issues with drainage than sloped roofs. The resulting pools of water will cause serious damage over time. This means extra care has to be taken when looking at pitch, evenness, and the seams between membrane sheets. If you’re looking to replace your flat roof, you want a team you can trust to do the job right.

Out with the Old

The first step of any flat roof replacement is to tear up the old, damaged roofing material. Like peeling back the layers of an onion, roofing teams work their way through every level of the roof. Starting with the exposed membrane, the crew will eventually tear right down to the decking. Some of these components have to be disposed of completely, while others can be reused if they prove undamaged.

Old Roofing Membrane & Insultation Removal

Roofing Membrane

Using some specialized tools and a whole lot of elbow grease, roofers pull away all the old roofing membrane, torch down or otherwise. Vents, skylight, chimneys, and other protrusions get extra attention, as these tend to be hotspots for damage and leaks. A flat roof’s membrane is its primary defense against rain, wind, and snow. As such, it’s subject to a lot of wear and tear and must be fully replaced.

Old Drip Edge Removal

Metal Drip Edge

The drip edge is a crucial part of the roof. On a completed roof, it directs water away from vulnerable areas and into drains. Unfortunately, when a full roof replacement is underway, it means the old drip edge’s time has come. The old drip edge is torn up and discarded with the membrane.

Foam Board Insulation

Under the top layers of the roof, you’ll sometimes find a layer of foam board insulation. Protected as it is from wind and weather, insulation can often outlast other components of a roofing system. Of course, leaks and water damage will compromise your insulation heavily. Additionally, the material does degrade a bit over time. Because of this, there’s a good chance some insulation will need to be replaced. However, much of it can be saved and reused in the new roof!

Old Roof Deck Removal

Roof Decking

The decking of your roof is the sturdy bottom layer that supports everything else. Typically made of plywood, OSB, or dimensional lumber on older roofs, most of a roof’s decking can usually be used again for the new roof. As always, areas that have succumbed to rot, mold, or water damage need to be cut out or pried up. Fortunately, these usually make up only a small portion of the decking.

In with the New

Once the defunct layers are removed from the old roof, it’s time to bring in the shiny new material. Aside from looking great, these new components will keep your house warm and dry for decades to come.

New Roof Deck Is Cut to shape for replacement

Decking Repairs

In the places where rotted or damaged decking has been removed, the decking is patched with new sheets of plywood or OSB. Because they were problem areas in the past, any areas where decking is replaced get special consideration from our crew. We want to make sure your old leaks don’t come back

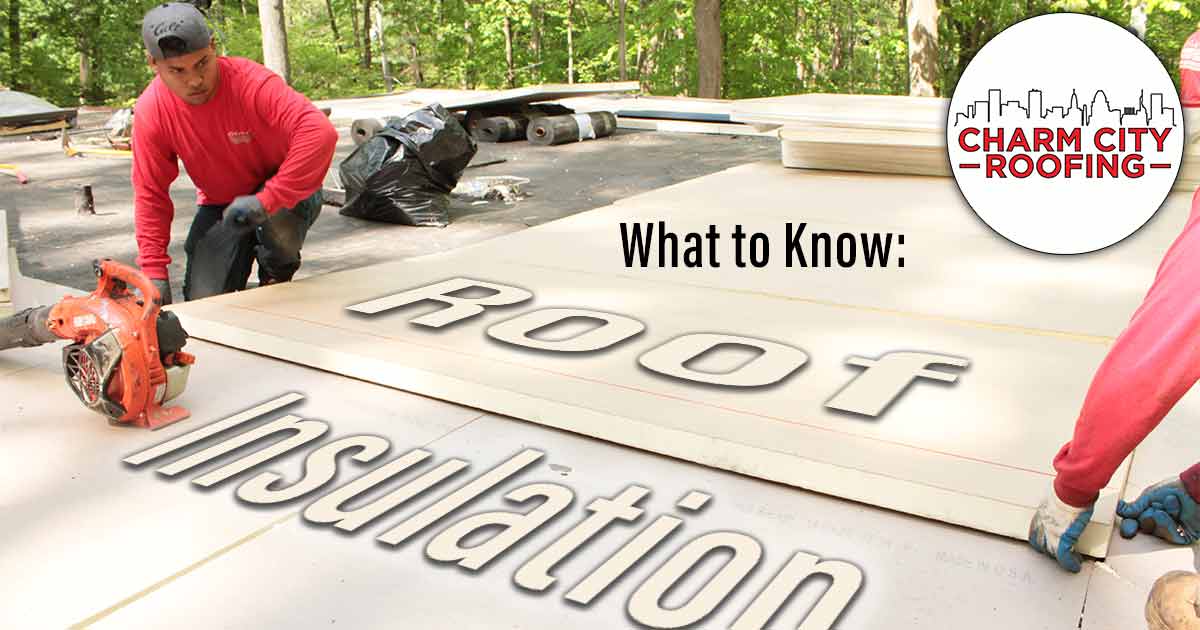

New Foam Board Insulation is Installed

Insulation Replacement

Unless it’s been damaged by leaks or is very old, insulation can often be reused in the new roof. Damaged insulation, on the other hand, is carefully removed and replaced with new material. Not all flat roofs require insulation, as the “plenum” between the ceiling and roof deck can act as a buffer on its own. However, extra insulation is hardly ever a negative. Though it can be viewed as an “extra” expense, the improvements to efficiency and performance tend to pay off in the long run.

New Self-Adhered Base sheet is applied down onto the roof

New Underlayment / Base Sheet

A new underlayment layer is critical to ensuring no water makes its way into your insulation and decking layers. It acts as a water shield that keeps your lower layers safe and dry. Underlayment also adds fire protection to your roof, and creates an excellent surface for the final torch-down layer to stick to.

In the past, underlayment was attached with specialized fasteners that punctured the underlayment directly. Now, we use an adhesive base sheet that creates far fewer opportunities for leaks and breaches. This means even better weathertightness and a more durable roof system!

New Perimeter Flashing is fastened to the edge of the roof

Drip Edge Replacement

Remember when we mentioned how important the drip edge is? Your new roof is going to need equally awesome flashing to make sure no water gets between the fascia. For every job, we custom-form the drip edge on site. The new aluminum barrier is then attached snugly to your new roof, right on top of the underlayment itself.

New GAF Rubberoid Torch Down Membrane is melted and applied to the roof

Fresh Torch-down Membrane

At last, it’s time for the main act. The torch-down asphalt layer seals the roof completely, covering the edge of the new drip-edge, and is the last necessary step of flat roof replacement. Propane torches are used to melt the rubber layer beneath, sealing it tightly to the underlayment. Special care is taken around vents, chimneys, and skylights, as these are hotspots for leaks. Custom cutouts are used to make sure every nook and cranny of your roof is 100% weatherproof. Extra flashing may also be added around these protrusions.

New White Silicon Coating on a flat roof replacement

Silicon Coating & Sealant (Optional)

For some flat roofs, a white silicon top coat is poured and “painted” over the torch down membrane. This liquid applied membrane evenly and seamlessly covers the roof for yet another layer of waterproofing. After applying a layer of priming compound, the liquid membrane coats and seals every inch of the roof, completely eliminating the seams and edges of traditional torch-down. The white silicon coating has the added benefit of UV reflection, keeping roofing surfaces cooler and generally more aesthetic.

Flat Roof Replacement – The Bottom Line

The process of flat roof replacement is straightforward, but that doesn’t mean it’s easy to do well. Getting the best roof possible requires a crew that takes the time to address the health of every roofing layer. Whether it’s attaching flashing, checking for insulation damage, or sealing everything up with torch-down, every step in the process is important. With care and attention, you’ll be left with a beautifully functional roof that will last for decades to come.

Author: Wilden McIntosh-Round